Our work method

Improvers Group provides unique opportunity for the planning and optimisation of complex saving programs. Let this be Lean, Process-optimisation, Six Sigma or Refa development project.

We aim at long-term strategic cooperation with our clients, during which through diagnoses we get to know the real development needs of the partner company, then by optimising several cost efficiency methods we create a unique development plan, taking into account the past developments.

- Lean Radar

- Lean sustainability diagnosis

- Barriers of development diagnosis

- Change implementation history

- Organisational stress assessment

As result of this we may achieve business targets in a more cost efficient way, because the method optimises the system’s resources.

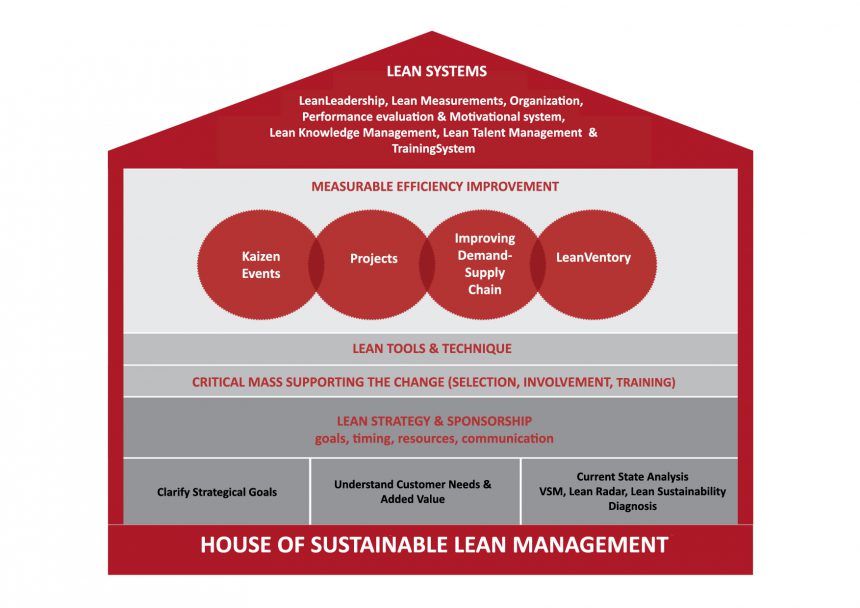

Establishing Sustainable Lean program

“Only one-fifth of companies establishing the Lean methodology is successful with results achieved by Lean” (Gemba Research)

IMPROVERS GROUP has performed complex Lean and Lean Sigma introductions for 12 years with British and American know-how.

- Harmonises organisation development processes with strategic goals, this way it is time and cost efficient, because companies usuall don’t have enough resources to start all kinds of development.

- Provides competitive advantage for the company in the globalised world: the organisation shall only introduce the best internationally used know-hows. The target is not only to be good, but to be outstanding.

It is important that the intervention shall bring permanent success for our clients, this is ensured by our LEAN SUSTAINABILITY methodology.

You can get more information on Sämling Solution Consulting home page.

Achieving dramatic process performance

Paradigm change starts with the selection of processes. In the traditional approach we spend a lot of time with the cost efficiency of existing processes. Outstanding companies were able to deeply understand their CORE activity before anyone else, and from that define their BASIC OBJECTIVES.

We optimise our Clients’ KEY PROCESSES based on this paradigm, and this way dramatic changes may be achieved.

Goals of process optimisation

- Minimising error possibilities

- Minimising lead time and cost utilisation

- Maximising value making abilities

- Maximising market and client change speed

Establishing REFA work systems

The optimally established work system, the process oriented working organisation, the management of business data are basic requirements regarding the competitiveness of companies.

We help the company to use people, materials and business tools in a way that by this they produce marketable products regarding costs, quality and transportation time.

The performance capacity and success of a company result mainly from economic workplaces and work processes.

With REFA methods the goal is to build new, process oriented organisational structure of companies. In addition to the application of the classic REFA-methods of time management we use the time definition method of process chains (lead times). More information about the courses and the counselling assistance: http://www.samling.hu/refa_kepzesek

Our references in numbers

- Lean projects: 100,000,000 HUF proven annual saving

- Kaizen Event: 50% performance growth of a carriage production line

- VSM/Kaizen Event: decrease of the realisation time of a maintenance measure with 25%

- Savings resulting from closed foreman Lean projects in two years (more than 30 projects): 150,000,000 HUF

- Expected annual saving of 165,000,000 HUF generated from middle-level Lean projects (20 projects) in one year

- American subsidiary employing 600 people in the field of machine production: Establishing Lean culture in a year with 300 million HUF loss saving (from EU tender resource)

- Optimisation of the processes of a Hungarian car industry subsidiary in German ownership before the introduction of VIR and production information system.

Contact us!

István Ecsédi

Phone: +36 20 923 54 05

E-mail: istvan.ecsedi@improversgroup.hu